Contact Us

Address: Anjiazhuang Industrial Park Of Jinzhou City, Hebei Province, China

Tel / WeChat: +86-13832332178

Tel: +86 311 84396930

Email: sales@hanformwork.com

Whatsapp: +86-15097331922

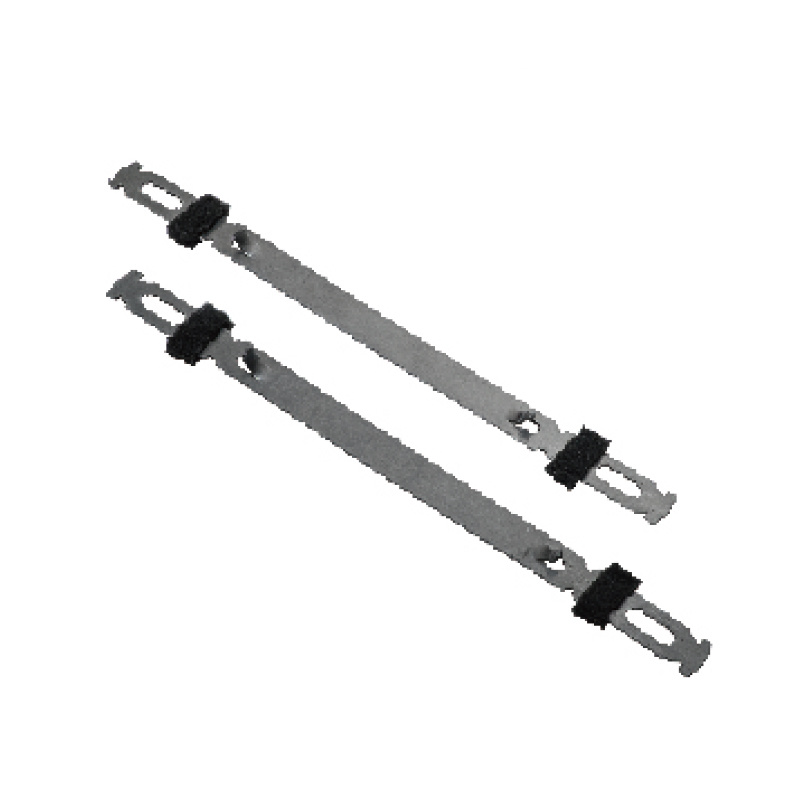

Support Clamp

- Commodity name: Support Clamp

- Product Description

-

Support clamps are essential tools in various industries, providing stability and security for a wide range of applications. From construction to automotive repair, support clamps play a crucial role in ensuring that heavy objects are properly held in place. In this article, we will explore the different types of support clamps, their uses, and the benefits they provide.

Types of Support Clamps

There are several types of support clamps available on the market, each designed for specific tasks and applications. Some common types of support clamps include:

1. C-Clamps: C-clamps are versatile clamps that are used for holding objects together or securing them in place. They feature a C-shaped frame with a screw mechanism that allows for easy adjustment and tightening.

2. Bar Clamps: Bar clamps are long, straight clamps with a sliding head that can be adjusted to various lengths. These clamps are ideal for holding large objects such as doors or panels in place during construction or repair.

3. Pipe Clamps: Pipe clamps are specifically designed for holding pipes and other cylindrical objects in place. They feature a circular frame that can be tightened around the pipe to secure it in position.

4. Spring Clamps: Spring clamps are small, lightweight clamps that are ideal for securing objects temporarily. They feature a spring mechanism that allows for quick and easy application.

Uses of Support Clamps

Support clamps are used in a wide range of industries and applications, including:

1. Woodworking: Support clamps are essential tools in woodworking, where they are used to hold pieces of wood together during assembly or repair. Clamps such as bar clamps and C-clamps are commonly used in woodworking projects.

2. Metalworking: In metalworking, support clamps are used to secure metal pieces in place during welding, cutting, or shaping processes. Pipe clamps and C-clamps are often used in metalworking applications.

3. Automotive Repair: Support clamps are also used in automotive repair to hold parts in place during maintenance or repair work. Spring clamps are commonly used in automotive applications due to their convenience and ease of use.

4. Construction: Support clamps play a crucial role in construction, where they are used to hold beams, panels, and other structural components in place. Bar clamps and C-clamps are commonly used in construction projects.

Benefits of Using Support Clamps

There are several benefits to using support clamps in various industries, including:

1. Increased Stability: Support clamps provide a secure and stable hold on objects, preventing them from shifting or moving during work. This increased stability helps to ensure accuracy and precision in tasks such as welding or woodworking.

2. Improved Safety: By securely holding objects in place, support clamps help to prevent accidents and injuries in the workplace. Workers can have peace of mind knowing that their workpieces are properly secured.

3. Enhanced Efficiency: Support clamps make tasks easier and more efficient by holding objects in place, allowing workers to focus on the task at hand. This increased efficiency can lead to faster completion times and higher productivity.

In conclusion, support clamps are versatile tools that are essential in a wide range of industries. From woodworking to automotive repair, support clamps provide stability, security, and efficiency in various applications. By understanding the different types of support clamps, their uses, and the benefits they provide, workers can choose the right clamp for their specific needs and ensure successful completion of their tasks.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Related Products