Contact Us

Address: Anjiazhuang Industrial Park Of Jinzhou City, Hebei Province, China

Tel / WeChat: +86-13832332178

Tel: +86 311 84396930

Email: sales@hanformwork.com

Whatsapp: +86-15097331922

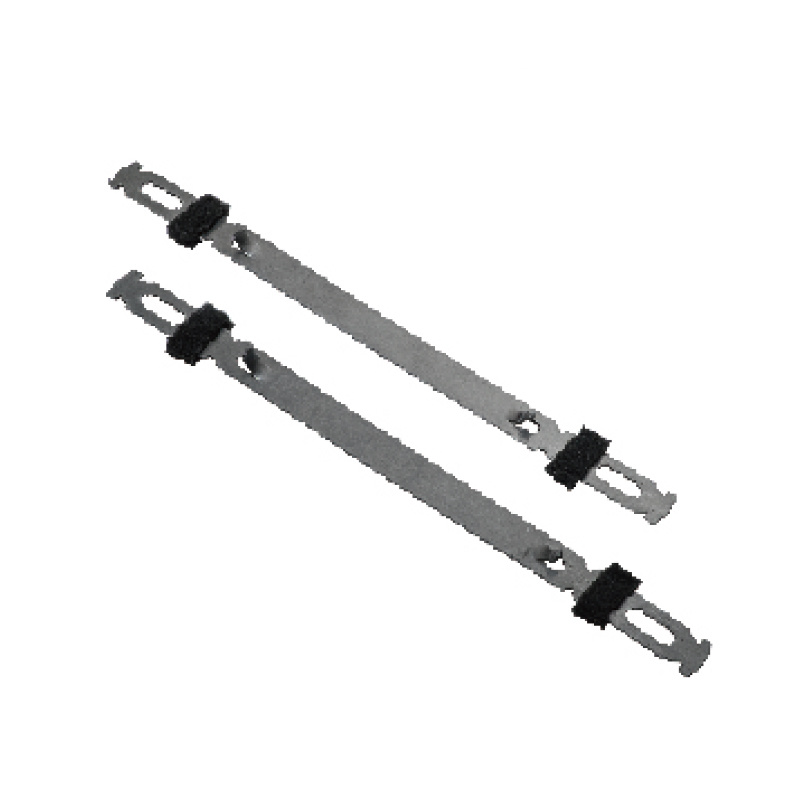

Steel Prop Accessories

- Commodity name: Steel Prop Accessories

- Product Description

-

Fasteners are essential components used in various industries and applications to join or secure two or more objects together. From everyday objects like furniture and clothing to heavy machinery and aerospace structures, fasteners play a crucial role in holding things in place. This article will delve into the types of fasteners, their usage, and the importance of selecting the right fastener for different applications.

There are several types of fasteners available in the market, each designed for specific purposes. Common fasteners include screws, bolts, nuts, washers, rivets, and nails. Screws are threaded fasteners that require a screwdriver to tighten or loosen them. Bolts are similar to screws but typically require a nut to secure them in place. Nuts are used in conjunction with bolts to create a strong and secure connection. Washers are thin plates used to distribute the load of a fastener and prevent damage to the surface being fastened. Rivets are permanent fasteners that create a strong joint by deforming the fastener or the material being joined. Nails are used to fasten objects by being hammered into the material.

Each type of fastener has its own set of advantages and disadvantages, making them suitable for different applications. For example, screws are versatile and are used in woodworking, construction, and electronic devices. Bolts are commonly used in structural applications where high strength is required. Nuts are essential for creating a tight and secure connection between two or more objects. Washers are used to prevent the fastener from loosening over time. Rivets are used in aerospace and automotive industries where a permanent and reliable joint is needed. Nails are commonly used in carpentry and construction projects.

The selection of the right fastener is crucial to ensure the integrity and safety of the structure or object being fastened. Factors to consider when choosing a fastener include the material of the fastener, the material being fastened, the load the fastener will bear, and the environment in which the fastener will be used. For example, stainless steel fasteners are corrosion-resistant and are ideal for outdoor applications. In contrast, brass fasteners are suitable for decorative purposes due to their attractive appearance. It is important to consult with an expert or refer to the manufacturer's guidelines when selecting a fastener for a specific application.

In addition to selecting the right type of fastener, proper installation is essential to ensure the fastener's effectiveness and longevity. Over-tightening a fastener can cause it to strip or break, while under-tightening can result in a loose connection that may fail under load. It is important to use the correct tools and follow the manufacturer's instructions when installing fasteners. Regular maintenance and inspection of fasteners are also important to ensure their continued functionality and safety.

In conclusion, fasteners are indispensable components in various industries and applications, providing a reliable and secure means of joining or securing objects together. With a wide range of fasteners available, selecting the right type for a specific application is crucial to ensure the integrity and safety of the structure or object being fastened. Proper installation and maintenance of fasteners are also important to maximize their effectiveness and longevity. By understanding the types of fasteners available and their respective uses, individuals and businesses can make informed decisions when choosing fasteners for their projects.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Related Products